A good farmer knows that everything made with his own hands is not only convenient, but also pleasant. Today, any craftsman can build a barn for his cow and make a convenient, proper container for food. Let's talk about how to make a cow feeder with your own hands right now.

Peculiarities

One of the most important items in arranging a stall for a cow is a container for food, that is, a feeder. We think this subject is important not only in cattle breeding, but also in other sectors of household farming. However, a cow feeder must follow some rules. Any container or trough will not work here. They should be different for different feeds: for dry and wet feeds separately.

The most important feeder is for hay and grass. It must be hinged and have a rectangular shape. To prevent food from spilling, many owners make the front wall lattice, but in such a way that the animal can easily stick its head between the partitions.

Wet mash and grain can be given in a bucket, as well as in a special plastic container. Today they are commercially available and used for both cows and horses. Most often, to save space, it is made hinged and corner, as in the photo.

From the point of view of convenience and hygiene, the most acceptable feeder is one that has a folding side wall and a grid for hay. It should also be possible to remove the container. In the summer, when the animal is on pasture, it can be dried well in the sun, and can also be easily removed and washed.

As for size, feeders from 100 to 120 centimeters in length are used for cattle. The width is usually about 60-80 centimeters, and the bottom width is 35-40 centimeters. The outer side is made up to 75 centimeters high. What options exist for homemade and purchased feeders, look at the photo in our article.

Manufacturing instructions

So, the easiest way to make a cow feeder with your own hands is from wooden boards. If you are not afraid to work with wood and know how to clean it properly, then such material will not only look natural and clean, but also comfortable. You can use pine or oak. Today there are three types of feeders: movable, folding and lifting. We will produce a lift with folding walls.

We will need:

- wooden boards;

- woodworking tools, grinder;

- measuring tape;

- drawing;

- steel rods or wooden slats.

Manufacturing

- First, we find suitable boards, dry them, clean them and sand them.

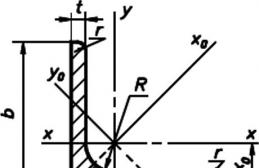

- We take the drawing and set the required dimensions: bottom width - 45 cm, width of the feeder itself - 80 cm, height of the outer side - 30 cm, inner side - 100 cm.

- On the inner side, for the convenience of the animal, we make a small recess for the head and neck.

- After the structure itself is ready, you can make a lattice from wooden slats or steel rods. It will prevent hay from scattering. For convenience, we provide several options for drawings of do-it-yourself feeders.

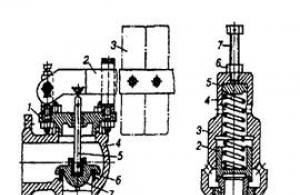

A - ground; b - height adjustable: 1 - side trough; 2, 3 - bent twig and tendril of the bucket holder; 4 — crossbar; 5 - feeder; 6 - riser; 7 - hole; 8 - stopper; 9 - bucket; c - tether feeder: 1 - side trough; 2 - feeder; 3 - collar; 4 - riser; 5 - chain; 6 - bracket

Video “Modern purchased plastic containers for cows”

In this video you can see what modern plastic containers for feeding cows exist, as well as what they can be used for.

Igor Nikolaev

Reading time: 3 minutes

A A

In barns for animals, it is necessary to install certain equipment. Among them are drinking bowls and feeders. Feeders or nurseries will not be the same for different foods. For hay and straw, a feeding table with gratings is made. They are necessary for animals to get food portionwise, in small quantities. Otherwise, the hay will be scattered all over the floor.

The farmsteaders accept this point, they say that scattered hay deepens the litter. Other feeders are intended for concentrates. The design ensures that animals can grasp it normally with their tongue and lips. They won't scatter it all over the stall. The containers are made without bars so that the grain mixture remains inside.

For juicy and liquid food, solid containers without a mesh are needed. They require constant washing, so they must be made of moisture-resistant, lightweight material. Which cow nursery is best for a stall and an open pen? How to make a feeding table with your own hands?

Types of feeders

For stall housing, cow mangers are most often made of wood or metal. Models can be different, mounted and stationary, rectangular and round. The farmsteaders themselves choose, taking into account which model will be more convenient for the animals, which feeder is more convenient to maintain. The dirt in them will attract insects that spread the infection. Leftover feed will rot. If animals receive poor quality nutrition, their immunity and performance will be affected, so it is important to choose a model that is easy to maintain.

- If you plan to make a stationary feeding table in the barn, then install it at a distance of 70 cm from the animal. It is separated by a partition. The inner side is made at the level of the animal’s knee, but no more than 60 cm from the floor. The outer wall is lowered to 30 cm. This is necessary to make it more convenient to distribute food. Stationary feeders are installed in stalls and open pens. They can be filled with both hay and combined feed. The table is made without the use of grates, as a single container. The material can be wood, plastic or metal sheets.

- Concrete mangers are often provided in the stalls. Convenient to clean. The material is moisture resistant. Concrete bowls are installed at a height of 60 cm. You can pour grain mixtures, chopped vegetables, and hay into them. Most often, concrete bowls are made using a frame, poured method during the construction of a barn.

- Plastic containers are often used for dry and wet food. They resemble elongated cylinders without a wall. They are made removable. They wash well. The plastic chosen is thick so that animals cannot break them. Containers can be removed and transferred to open pens by placing them in a pre-prepared frame.

- A chute can be used as a manger for a cow. It is made from pipe. The pipe is cut lengthwise and installed on the frame. Wash it under strong pressure of water. It will last a long time. The pipe must be thoroughly washed, painted, and the edges treated so that the animals cannot get hurt. Gutters are made both in stalls and when animals are kept freely.

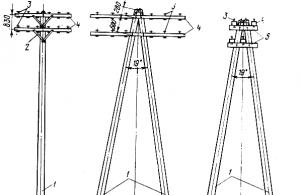

- In the summer, animals are grazed, but they need to be given hay. Stationary and mobile feeders are made especially for hay. A popular model is one that resembles a children's round playpen. The playpen has a bottom so that the hay does not come into contact with the ground. The bottom is raised at a distance of 30-40 cm: the height can be adjusted. A bale of hay is placed in the arena. The walls are represented by an inclined lattice. The distance between the slats is 120 cm. This is enough so that the animals can get food normally without damaging the horns. The playpen can be placed on its side and rolled to another place.

It is not recommended to feed a calf a lot of hay. At six months they are given no more than 2 kg. The nursery is made in a small size. They are a rectangle made of planks. The distance between the slats of the grid should not exceed 5 cm. This is quite enough for the young animals to get the hay and not scatter it in the paddock.

For liquid feed, grain mash, plastic buckets are provided if the young animals are kept in stalls. In free pens, troughs are installed for them. They are placed at a height of 40 cm from the floor.

Each product requires a design and drawing. It must be done on a sheet of paper, or better yet, embodied in the form of a small model. These measures will allow you to correct any shortcomings and select the right material. The wood chosen is 1st grade, without knots or traces of mold. Thickness 20 mm. The boards are sanded and dried. Roughness and sharp corners can injure the nasolabial triangle of animals.

The feeder for a stall with a tethered housing method can be made in the following dimensions:

- the wall on the animal side is 60 cm high; a recess is cut out in its center: 30 cm wide, 10 cm deep; it is necessary so that the animal does not rub its skin on the box when feeding;

- front wall 30 cm;

- bottom width 40 cm;

- width along the top bar 60 cm;

- box length 120 cm;

- You will need brackets on which to hang the feeder.

Blanks are made from boards. All blanks are connected with nails, which are hidden so that animals do not get to them. Sometimes glue is used, but this material is not very effective. At high humidity, the glue loses its properties.

This feeder is made without bars, but on the top bar of the stall you can attach a mesh that would serve as a lid. The animal will go to the box, moving the net with its head, take away the hay, and remove its head. The mesh, when closed, will not allow the animal to grab a large bunch. Hay will be used rationally.

How to make a metal feeder?

A free-standing animal feeder can be made of wooden slats or metal pipes. In order to make a manger from metal, choose pipes with a diameter of 13 mm. The feeder will be durable, but working with metal requires skill. To work you will need a welding machine.

The drawing shows the following dimensions:

- upper rectangle 210*65 cm; you will need 2 pipes of these sizes;

- the height of the rod for the grate is 70 cm; you will need 26 of them; they are located in increments of 70-100 cm, 13 pieces each. on each side of the top rectangle;

- the rods are attached to one pipe from below, 210 cm long; the pipe is located in the center of the rectangle: it goes along;

- the end walls of the feeder form triangles; for structural strength, a pipe is strengthened from the base to the top of the triangle;

- the entire structure is installed on a frame: width 64 cm, length 210 cm, height 90 cm;

- The frame is installed on legs: height 40 cm.

Animals will have the opportunity to approach the feeder from both sides and take hay. Since the top of the feeder is wide, it will be convenient to replenish it with hay or straw. This feeder is installed in both open and closed pens. It is better to install it under a canopy that will protect the food from precipitation. If you place the manger with hay on a low podium, it will be more convenient to collect it and put it back. Animals will not trample food into the ground. The height of the podium can be 30 cm. The length and width are 1.5 m larger than the dimensions of the feeder.

The nursery can be made of metal pipes shaped like an arc. The arches are strengthened on a rectangular frame in increments of 10-15 cm. The product will be heavy. You won't be able to move it. It is most often installed in open areas.

All metal components are treated with anti-corrosion mixtures and painted. For products, exclusively pipes are used. They have a rounded surface. Corners are not recommended. Cows can get hurt by them.

Hay can be freely available to the livestock. Dry mixtures are given strictly in doses. Overeating can provoke pathologies in the rumen and gastrointestinal tract. Separate boxes are most often used for dry concentrates. They are filled during milking of cows.

In a barnyard, a cow feeder is a must-have item. Keeping cattle without this element is very difficult. This device is convenient for both parties. Firstly, on the part of the farmer - proper maintenance of the animal, convenient feeding, ensuring cleanliness in the barn. Secondly, for livestock - timely nutrition and watering, as they need to maintain a balance of nutrients. Containers must be manufactured and installed according to various rules, which will be discussed in the article.

Brief information

All farmsteads and farms where cattle are kept are equipped reliably and functionally. You also need to remember about convenience. Properly located containers for food and drink provide comfortable living conditions. The container must be suitable for dry and wet food.

Hay and grass are usually placed in hanging rectangular containers. Due to the fact that cows have a habit of scattering food or digging it, it is advisable to make a wall in the front in the form of a lattice. Through it, animals will also be able to get the required amount of food.

For liquid food, the feeder is made of plastic, but buckets can also be used. Of course, it is desirable to be able to secure them so that cows cannot turn them over. The container is installed so that it is convenient to remove it later for cleaning and washing.

In any case, every type of barn feeder needs to be cleaned periodically, so they must be removable.

Pasture container

If cattle are kept in a stall-pasture system, then all feeding areas must be equipped according to the rules. This is necessary to ensure maximum functionality - less feed loss and more feed consumption, as well as good capacity. At the same time, workers do not put in additional effort.

On pastures it is also necessary to install feeders for livestock, especially during periods when there is little vegetation. Typically, there is a shortage of greenery in the autumn. Hay is often stacked in small stacks, but this option is very wasteful. The product is pulled away or trampled into the ground.

An excellent way out of the situation would be feeders made in the shape of a cone or an inverted triangle. They can be of any convenient length, and the side walls are in the form of rods. A special tray is installed at the bottom, into which small blades of grass are collected. A roll of hay is placed in such a container and it lasts for a long time.

Feeding with grain or mixed feed can also occur in walking areas. Even if there is plenty of greenery, dairy cows and animals with calves need additional nutrition. In this case, automatic feeders are used. The advantages are that the food is supplied continuously, but in small doses.

Often calves are also fed with the help of such a device, but only with special fences from adults.

Cow table in the barn

The feeder for bulls and cows in the barn is located mainly in the passage. This is a kind of corridor, which is raised above the floor by several cm, from 10 to 30. On one or both sides it is enclosed by walls approximately 50 cm in height. This prevents food from getting under the animal's hooves, and manure does not mix with food. Another advantage of this table is that it is very easy to make, as well as to clean it from food debris and dirt.

If the livestock is large, then a feed mixer helps. This is a kind of mixer that mixes feed components. It can be combined with a feed dispenser, which places food in feeders.

Farms are of the tethered type. In this case, the animals are fixed, and the table does not require additional fencing. If the cows are not tied, then special grates are made that will not allow unsecured cattle to enter the table. They come in three types:

- inclined – this is a better way to secure livestock;

- vertical – animals move more freely and can interfere with each other;

- automatic fixation is a modern method that can be useful for other purposes - veterinary examination, insemination and various other procedures.

If the stall or barn is small, then you can make a hanging type feeder. When the livestock does not exceed 10 cows, production automation is not required. In this case, an individual approach is welcome. Containers can be for different types of feed - liquid and rough. Wet food is not always present in the diet, but hay, grass, and straw are used constantly, so you cannot do without containers for them.

Making a container for food

Now let's talk about how to make a cow feeder with your own hands.

One option is a container with folding walls. Wood species such as pine or oak are suitable for it. To build a feeder, you need to work with the material correctly, be able to clean it and then use it.

For manufacturing you will need boards, a plane, a jigsaw, a saw, a tape measure, slats or fittings. First you need to prepare a diagram of the product. Standard dimensions are taken, where the width of the feeder is 80 cm, the bottom width is 45 cm, the height of the inner side is 100 cm, and the height of the outer side is 30 cm. The material is dried, cleaned and polished, and then fastened together with nails. For ease of use, it is advisable to make a recess on the inner side for the neck of the cattle. Slats or fittings are attached to the finished product in order to avoid spillage of feed.

The feeder for cattle can also be a group feeder. Its production technology is more complex, since the structure is metal. It may require pipes, a grinder and a welding machine.

Drinking bowl

Animals in a stable, especially high-producing cows, need sufficient fluids. They can drink up to 100 liters of water per day. The drinking bowls should have free access, and they themselves should always be filled. If there are few of them, then basins, buckets, and troughs are additionally used. But here it is necessary to ensure that the containers are not overturned. Again, it all depends on the number of heads in the stable.

If the farm has a large population, then a group drinking bowl will be just right. The simplest option is a large-diameter polypropylene pipe, cut lengthwise. It is welded at both ends and an acceptable container for water is obtained. It can be used on pastures where there is no running water.

There are also more complex options that are used on farm complexes with running water. For example, the float model resembles the action of a flush cistern in a toilet. When the volume of water in the tank decreases, the liquid is supplied automatically to the desired level.

There is a valve model. In this case, when drinking, the cow presses the lever with her nose, supplying water. A violent animal can easily damage such a system.

If you liked the article, then like it.

We are also waiting for comments on the topic of feeders for cattle.

One of the most important points when building a barn is stall equipment for cattle. It is needed both for a large herd and for a small family farm. The article will talk about it in more detail.

The choice of stall depends on how the cows are kept. The main requirements for it are practicality, combined with the idea of convenience and safety for animals. It includes:

- various limiters;

- feeder;

- drinking bowl

Stall equipment for cattle

On a note. It is convenient when stall equipment can be assembled without additional effort, without using welding or other original methods. Water can be obtained from a nearby well.

Equipment for loose cattle

With this method of housing, the main area of the barn is divided into separate pens. All along the barn, holes are made using metal parts, through which a cow or calf, sticking its head through, can take food and drink water.

Each free-stall pen contains a small number of cows, which have the opportunity to move freely within it. They are not able to get from one pen to another.

To get food, they must go to the desired edge of the pen and stick their head to the feeder.

Equipment for tethered cattle

To use this method you need chains or belts. In this case, the cattle are tied loosely by the neck so that the cow or bull can easily reach the feeder and drinking bowl. In this case, the animal does not have the opportunity to roam freely between the stalls.

Equipment for tethered cattle

An environment is created for the livestock to which they gradually become accustomed. In this case, the cattle are positioned so that there is a level cement floor behind them with a slope towards the ditch. This makes it possible to remove manure after cows as needed.

The dimensions of the stall for tethered bulls are usually no more than 120 by 260 cm. If the bull is an adult intended for insemination, the space provided to him may be larger.

Feed dispenser for cattle

To help in servicing animals, a special device is used - a feed dispenser for cattle. All portions of food are immediately loaded into it, then, moving along the aisle, it measures the required amount of food into the cow feeders.

Using a feed dispenser, you can organize the supply of haylage, silage, green feed, and forage mixtures for cattle. This mechanism provides the ability to distribute food to both one and both sides of the passage along which it moves.

Such devices must meet the following requirements:

- Food must be distributed to the entire barn in no more than 30 minutes.

- Safety standards must be followed. In this case, you need to think not only about the farm workers, but also about the livestock. In particular, electrical safety requirements must be taken into account (animals should not be harmed by old faulty wiring). If there are any malfunctions, repairs must be carried out immediately.

- The portion of food supplied to each nursery must be accurately measured. The deviation should not exceed 5% if we are talking about concentrated feed. For hay, the accuracy is 15%.

- It is unacceptable when food stratification occurs when feeding food into a feeder for bulls or cows.

Feed dispenser for cattle

Interesting. Existing models of feed dispensers for cattle farms can differ in load capacity, distribution method (on one or both sides), be mobile (moved on wheels with tires like a car) or permanent (installed inside the farm).

Electronic scales for cattle

When raising livestock, it is important to control the weight of each animal. For this purpose, special electronic scales are used. Their main distinguishing features:

- The scales are capable of working with fairly large weights: 300-5000 kg.

- The size of the weighing area can reach 3 by 5 meters.

Scales for cattle consist of the following three parts:

- weight platform;

- fencing;

- indicator where weighing results are shown.

Electronic scales for cattle

Additionally, the kit may include:

- A ramp that allows the animal to easily enter the weighing area.

- Sometimes the kit includes wheels to make it possible to move the scales around the workshop.

- An additional indicator where you can see the weighing results.

Metal parts of cattle equipment must be protected from rust.

The operating principle of electronic scales is to use strain gauges, which are located at the four corners of the weighing platform. Each of them simultaneously serves as a support and allows you to read data to determine the weight of the animal.

Scales must meet the following conditions:

- They must ensure stabilization of the determination of the animal’s weight.

- It is necessary to be able to accurately set the zero.

- Possibility of taking into account tare weight.

There are two installation options. In the first, simpler case, they are simply placed on a flat area of the floor. In the second case, a recess is made in the floor into which the scales should fit. In this case, the weighing surface will have to be level with the floor. This option requires additional work during installation, but is more convenient for livestock.

Ventilation on a cattle farm

Ventilation on a cattle farm

At the same time, air accumulates inside, which contains cow waste, dust, and dirt. It becomes a source of health problems for the animals inside and the people working there. In particular, this has a bad effect on cattle productivity.

Note! Well-functioning ventilation can solve these problems.

What you can do with your own hands

In some cases, it is possible to make useful devices yourself. Here are two such examples.

Cow feeder

If you need a do-it-yourself cow feeder in a barn, you can make it as follows.

To make a feeder in a barn you need the following tools:

- roulette;

- boards;

- hand saw;

- plane;

- wooden slats.

Step-by-step instructions for operation:

- First you need to make a drawing of a hay feeder for cows. This will be an open top box. The dimensions of its bottom are 45 by 80 cm. The height of the far edge is 1 m, the near one is 30 cm. A semicircular recess is made in the front part. It is designed for the neck of a cow.

- The boards need to be cleaned with a plane. They should be smooth and fit snugly together.

- We nail the boards and as a result we get a box for the feeder.

- We attach a frame of slats to the near wall. When feeding, the cow will have to stick her head into it and while eating she will not be able to scatter the feed.

Cow feeder

Now the cattle feeder for hay is ready.

DIY vegetable cutter for livestock

You can make your own vegetable cutter for livestock at home. To do this, you need, first of all, two components: certain skills in working with metal and a working electric motor. For example, you can use the one found in an old washing machine.

The work is performed as follows:

- You need to take an old bucket or other similar metal container.

- It is necessary to drill a hole with a diameter of 1 cm in its bottom.

- A rectangular hole is made in the lower part of the side surface of the bucket, the width of which should be no more than one and a half centimeters, the height - approximately 7 to 10 cm. The edges of the cut metal must be bent outward.

- The motor axis is threaded through the round hole from below. Two knives are installed on it, having different purposes. One of them must be sharp. It is designed for cutting vegetables. The other has the side edges slightly curled. He pushes the crushed mixture into the holes, and throws some pieces up so that they fall under the knife again.

- To prevent vegetables from flying far, you need to attach a curtain to the outside of the hole.

- The motor is attached to the bottom of the bucket, and the entire structure is mounted on metal legs.

When chopping vegetables, place a container under the outlet hole into which the chopped food falls.

Restrictors are usually made of metal. To increase their durability and to protect them from animals, it is necessary to treat them in one way or another to prevent rust. One of the common methods is to galvanize metal parts.

In order for the air quality to be high, it is necessary to equip an air purification system using fans, special adjustable curtains and other such artificial devices.

The benefits of drinkers and feeders

To produce the required amount of milk or meat, the cow must drink enough water. For 1 liter of product you need approximately 4 liters of liquid, that is, 60-80 liters per day. It is worth equipping special feeders and drinking bowls for cattle for several reasons:

- Cows will not throw food at their feet. This will ensure its cleanliness and reduce consumption. The time needed to clean the stall will be reduced.

- It will be possible to dose the feed and regulate the components of the diet.

- The water will always be fresh, and cleaning the drinking bowls is easy. The devices are compact.

- Animals will come to a certain place. This will make it possible to inspect them if necessary and pacify the violent ones.

If the farm is large, it is better to equip automatic drinkers. Weather and types of food affect the amount of water in a certain way. An unstable bucket is often used to feed calves, but the owner must control the process.

Requirements

The herd must be protected from various types of damage. To make a cow feeder with your own hands, you need to choose the right material. It shouldn't be toxic. This requirement meets:

- tree;

- cast iron;

- stainless steel;

- durable plastic that does not contain harmful substances;

- brick;

- stone.

Lead and similar metals are not suitable. Wooden products are not coated with paint or varnish.

Drinking bowls and feeders are designed so that animals do not litter. Pregnant cows and young animals should not drink cold water. The structures should not have sharp corners or protrusions.

If livestock are not tied, drinking structures are placed close to feeders. To prevent cows from touching the edges of the structure with their larynx, it is worth maintaining a distance between them and the floor. Feeders should be spacious.

Types of drinking bowls

The main purpose of the devices is the timely supply of water in the required quantities. Today farmers use two types of drinkers:

- Individual - when the cows are tied.

- Group - when animals are not kept on a leash. They can be portable or stationary. The former are used in pastures, the latter in barns.

Level structures are often found on farms. The principle of their operation is to supply water in portions. The pressure makes the device work and provides fluid to several animals at once. The disadvantage of such a device is its unhygienic nature. There is a risk of spreading infections.

DIY drinking bowls

A plastic container is most convenient. It lasts a long time and can withstand temperature changes. Stainless steel is often used for the manufacture of group structures.

Simple device

At home, simple structures are made: they hollow out a recess in the deck, secure a bucket, plaster it and arrange a drain. Water is poured as needed. Make sure that the cracks are well sealed, otherwise the fluid consumption will increase.

For large farms, structures are made in the form of a toe or gutter. A pipe is connected to them from the water supply. The liquid is supplied using a valve. Individual watering stations are installed for bulls or heifers. The milk drinker is capable of feeding 8-10 heads of young animals.

Another simple method of group watering is a large-diameter sawn pipe with welded ends. It is often used on pastures where there is no running water.

Automatic adaptation

Provides animals with water at any time and in unlimited quantities. Making drinking bowls for cows with your own hands begins with constructing a separate tank.

Valve-float design

The name explains the water supply scheme. It is identical to the operation of flushing a toilet cistern. Creation consists of the following steps:

- the vessel is fixed at a height;

- the flow of water into the drinking bowl is ensured using a pipe;

- so that the liquid stops flowing, use a damper attached to the rocker arm;

- A float is installed in the automatic drinker and its other end is secured.

For the design to work, the float must be heavier than the damper. It will lower as the liquid level drops. Then the valve will rise and liquid will flow. When full, the valve will close again. The winter structure is equipped with heating.

There is no point in making an individual drinking bowl for cattle automatic. The device is used to provide liquid to many heads.

Cup design

The description of the operating principle is similar to the previous one. The difference is that the automatic drinker in the form of a bowl acts as a valve. As the water decreases, it rises and the damper opens at the same time. When filled, the container lowers and the valve closes. This type is great for tethered cows. The main problem with the cup design is to teach cows to drink from such containers.

Nipple design

It is difficult to make it yourself. Not everyone knows how to make a nipple, so it’s easier to buy one. The size of teat drinkers for calves depends on the age of the babies. In order for young animals to learn to drink using a device, you will have to make an effort.

DIY feeders

Designs must be functional. They are installed to reduce feed consumption.

Simple devices

If the livestock is small, a feeder is often made from any tree. It is better not to use chipboard, especially if the barn is humid. The cross-section of the structure should be in the shape of a trapezoid. The dimensions are as follows:

- about 80 cm deep to accommodate the head;

- 80 cm wide at the top.

It is better to install a vertical sheathing at the front. This livestock feeder will last a long time.

Pasture

Hay in the form of bales or in bulk is mixed with manure. During the cold season, a feeder is an excellent solution for providing animals with food. First, they decide on a project and select a drawing.

To make it convenient for cows to get feed and not throw it away, a cylinder-shaped design is often used. It is blocked from below, which allows small fractions not to fall out. The edges are covered with sheathing. The advantages of the design are as follows:

- cows cannot get a large amount of hay at once;

- strength and durability;

- avoiding injury to cows.

A homemade hay feeder can be square in shape. In this case, the lathing is made vertical. The costs for manufacturing such a design are small. The downside is that cows or bulls get stuck between the bars, which causes injury.

Do-it-yourself drinking bowls for cattle

Gas cylinder for drinking bowls

Conclusion

Ensuring optimal living conditions makes the farm profitable. The type of feeders and drinkers is chosen depending on the direction, the number of heads and the means.

Drawings can be found on the Internet or in special publications. This design will provide the bull or heifer with the necessary amount of milk until they switch to adult food.