Every dacha owner dreams of a convenient and multifunctional grill, which will allow you not only to cook various dishes over an open fire, but also to smoke meat, fish, poultry, and homemade sausages. You can make a small brick, stone, metal grill or a spacious grill house with your own hands if you put in some effort and purchase the necessary materials and tools.

Grill - general design

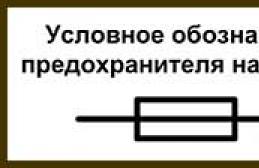

In its design, the grill resembles a box with a lid, which is made of heat-resistant materials, for example: concrete blocks, refractory bricks, as well as stone or metal. The shape of the grill is a deep frying “barrel”, which ensures ideal roasting of food on all sides due to the maximum temperature of the coals. The lower part is for fuel, and the upper part is for storing food. There are holes with flaps in the bottom and cover of the device body that serve to regulate the flow of air that flows inside. But there are other types of grills: gas and electric, which do not require a chimney or solid fuel.

Device height

The installation height of the grill can be determined based on the comfort of use, as well as safety measures. The gratings are installed at a height convenient for humans. If it is a brick structure, then they should be at a height of approximately the 10th stack of bricks from ground level. If the grates are positioned higher, it will be inconvenient to cook food, and placing coals close to your face can lead to burns.

In standard devices, the coal tray, together with the grates, rests on brick protrusions or special metal rods, which are installed in the masonry. Also, the grill mounting design must provide for the ability to quickly remove these additional elements, which are dismantled for the winter. This will help protect metal parts from corrosion.

Additional grill equipment and its design

In the design of the grill, it is necessary to make the correct draft so that the smoke does not go into the room, but goes out into the chimney pipe. When planning the grill structure, you will need a drawing of the working surfaces and additional shelves.

It is necessary to determine the place where the plates and coal supply will be located. Brushes, tongs, spatulas and other utensils can be stored on hooks installed on the side wall of the grill.

The design characteristics of the grill provide thermal action and permeation of food with smoke, as well as smoking them.

This device additionally serves as a smokehouse, and therefore has a more complex design.

How is it different from barbecue and barbecue?

With the onset of summer, we go to the dacha to relax, work and eat delicious kebabs and smoked fish. It will be very easy to prepare food if you have a grill, barbecue or barbecue at hand. Let's look at how these devices differ from each other and how they are similar.

- The grill looks like a metal rectangular box with high legs. Food (meat, fish, vegetables) is skewered on skewers and placed on the grill parallel to each other. Dishes are cooked using smoldering coals. To improve draft during cooking and provide the grill with better air flow, you need to periodically fan the coals. The advantage of the barbecue is its ease of use and low price.

- A barbecue is a more complex and advanced design as manufacturers often upgrade it with numerous features. In the device you can bake pies, heat up dishes, smoke, stew and fry. There are gas, electric and coal. In a barbecue, food is cooked on a grill.

- The grill has no obvious differences in design from the barbecue, and some see them as identical. Although there is still one difference - the presence of a lid on the grill (thermal exposure occurs from all sides), so the food in it is cooked more evenly. The lid of the device also makes it possible to saturate dishes with smoke. The main element is a wire rack with wire and wooden handles that allow you to firmly hold food while cooking.

Preparing for the construction of a grill: design drawings, dimensions

The process of building a grill will require a lot of responsibility. The first step is to decide on the grill design and its dimensions.

At the moment, there are a huge number of modern PC programs that allow you to create a 3D model of a structure. Therefore, if you have basic skills in working with programs, then use them. If there are no such possibilities, then the project can be drawn up on plain paper.

The design must take into account the most important design requirements. The optimal grill sizes may be:

The choice and quantity of material for constructing a grill with your own hands

The grill can be built from various materials depending on the dimensions of the structure and its type (portable or stationary). Let's look at several grill options that are most popular today.

The grill can be equipped from a gas cylinder:

Grill benefits:

Stationary brick grill

A brick grill will require additional skills during installation, but it has a number of advantages:

Grill house

The Finnish grill house is the most convenient and comfortable option for a summer house with a large area.

To build such a structure we will need:

- insulation (can be made of mineral wool);

- high-quality lining;

- door and double glazed windows;

- washers with nuts according to the size of the holes;

- polyurethane foam (several cylinders);

- chimney, as well as smoke collector;

- gravel is medium in size;

- river sand (preferably not washed);

- any curb stone;

- small paving slabs (if the floor is not wooden);

- crushed stone;

- OSB board (best waterproof);

- plastic pipe with a diameter of 18 cm for blowing;

- "Pinotex" is a special product intended for processing wood;

- edged board for making a roof frame 50x100 mm;

- timber with a section of 80x80 mm, 1.5 meters long and 100x100 mm, 2.5 m long - 6 pieces;

- tiles (bitumen, soft, natural) for roofing or metal tiles;

- windproof film;

- additional elements for decorating the building.

Tools:

Stages of building a grill house with your own hands

The Finnish grill house is a whole complex of hexagonal shape with a pyramidal elongated roof, as well as a general closed structure.

- To begin, we select a round area and remove part of the soil from it with all the existing roots of plants and trees.

- We fill the site sequentially with three layers of materials: crushed stone, the next layer is sand and the final layer is fine gravel.

- We lay in advance a plastic pipe intended for blowing.

- We compact all layers tightly and begin reinforcing the concrete screed. We leave a place in the center where the pipe will be laid in the shape of the letter “P”.

It is necessary to determine the functional purpose of the dacha structure immediately before the start of construction

- We install a slatted floor made of wood or paving slabs. Along the edges of the inner perimeter of the house we install curbstones for additional safety.

- The next type of work is the manufacture of the frame. To do this, we install six support beams with a cross-section of 100x100 mm and a length of 2.5 meters.

- Next, we perform a horizontal connection of the main beams using 80x80 beams 1.5 meters long. We repeat this connection in 3 places: first at the bottom, then in the middle and at the top. After such actions, carefully measure the angle between the elements that were secured with a square. Optimally, each angle should be 60 degrees (a deviation of 1 or 2 degrees is allowed). Next, you need to fasten the bars: use an electric drill to make holes, and then insert self-tapping screws and metal corners into them.

- We assemble the roof frame. We use prepared boards with a section of 50x100 mm. The finished base of the structure should have 6 identical corners. And the internal diameter completely corresponds to the pipe of the device. As a roof connection we use an edged board with an identical cross-section.

- We insulate the roof with mineral wool, and put a windproof film on top. We make the roof from natural or soft tiles. You can use reeds or straw mats for roofing.

- The entire structure is sheathed inside with clapboard or other cladding lumber, and on the outside with moisture-resistant OSB boards and decorative wood panels (siding, wooden boards or clapboard for exterior use).

- We insulate the middle layer between the walls with mineral wool or other heat-insulating material.

- We install wooden or metal-plastic windows and doors.

- The surface of the house (if it is wooden) is treated with glazing fire retardants, which will protect the structure from rot, mold and bark beetles.

- We cover the ceiling with clapboard. Leave a hole for the chimney in the center of the house as shown in the photo.

In the center we install a Finnish grill, which can be bought in a specialized store.

Finnish grill is installed in the center of the house

Video: Finnish oven for grill house

You can build a Finnish grill with your own hands. Since a brick grill is a lightweight structure, we need a small foundation. We prepare the following materials:

- premium-grade refractory and facing bricks;

- fireclay brick for firebox;

- cement for the foundation (grade 100 is possible);

- river sand for mortar;

- gravel;

- boards for formwork;

- roofing felt or tar for insulation;

- reinforcement for the foundation.

Tools:

- rubber hammer;

- trowel and set of tools for laying ready-made mortar;

- plumb line and level for measuring horizontal and vertical walls;

- template for a semicircular arch;

- grinder with diamond cutting discs and grinding wheels;

- saw for cutting bricks.

Stages of constructing a Finnish grill

We build a Finnish grill ourselves:

- We mark the foundation using pegs and twine.

- We dig a hole in the center of the gazebo, but leave a small margin of 5 cm wide and 30 cm deep.

- We fill the bottom with slag and tamp it thoroughly.

- We arrange formwork around the entire perimeter of the grill, and place reinforcing metal inside.

- We mix the concrete and pour it into the formwork, then wait a day for it to harden.

- We make a screed, let it dry, and lay roofing felt or other waterproofing material on top.

- We decide on the shape and size of the openings for the grill. Corners are needed for rectangular openings that will serve as lintels. A wooden template is made for the arched vault.

- Using the hardened mortar, we make half-brick masonry, leaving openings. Their height should be 60 cm if the opening is arched (with a rectangular one 80 cm). We lay a brick with strapping around the entire perimeter so that the height of the grill is about 1 meter.

- The second brick tier includes the walls of the grill and its firebox, which are made of half a brick.

- To construct the firebox, we take several types of bricks. We line the bottom of the grill and the inside with fireproof material, and make the outer masonry from ordinary white or red brick. The result should be 2 rows. The firebox should have an opening height of 7 brick rows. The laying of a rectangular arch involves about 9 rows. The depth of the element is 60 cm and its width is 70 cm.

- We lay about three rows of bricks above the opening. Then we make a pipe, which is a narrower element, which means there is a need to shorten all sides of the firebox. Subsequent rows for all walls are reduced by 1⁄4 of the length of the brick, for side rows this will be half the width of the brick. In this way we lay out 7 rows and form a narrow pipe.

- Next, we lay out 14 rows only straight.

- The entire masonry should stand for several days until the cement mortar dries completely.

- We install wide benches along the wall, which can comfortably accommodate up to 10 people.

Video: how to make a grill house with your own hands

How to make your own smoker grill

A steam locomotive or smoker grill is a multifunctional but complex structure that combines a barbecue, a smokehouse and a grill. But even such a seemingly complex device at first glance can be made with your own hands.

To make a smoker grill we need the following materials and tools:

- barrel;

- loops;

- bolts;

- nuts;

- wooden handle;

- metal pipe or angle;

- wooden lining, WPC or treated boards;

- gratings;

- welding machine;

- Bulgarian.

Stages of making a smoker grill

If you are using an old barrel, bake it thoroughly before preparing food for the first time.

- We cut the barrel into two parts lengthwise using a grinder. Since they will turn out to be the same, one of them will become a container for fuel, and the second will become the upper part.

- We connect the base of the structure and the cover with two loops using bolts. We drill a hole with a drill.

- We secure the wooden handle to the lid with a bolt tie. Its length should be no more than 50 cm, and we will adjust the distance between the base and the handle with several nuts.

- We make the frame: its length should be approximately 30 cm greater than the length of the barrel itself, its height should be 80 cm, and its width should be 5 cm less than the diameter of the barrel. We fasten the frame elements with bolts and nuts. In this case, you can use a welding machine.

- After the metal frame has been made, we install the already made barrel on top and make wooden tabletops around it.

- Next, take 2 grates of different sizes. We place the smaller one on the bottom of the grill, since it is intended for fuel, and we place the second one above the coals on top - food will be laid out on it. We make stops for it using thick bolts, which we screw around the entire perimeter of the grill.

- The smoker grill is ready. You can make a multi-level option. To do this, you need to take another barrel, only a smaller one, which will serve as kindling for coals and weld it to the main barrel, only a little lower (ladder principle). The rest of the device is made in the same way as described above.

Video: how to make a smoker grill with your own hands

Any type of grill will be a decoration for your area and a place to relax. A grill house built with your own hands will serve you for many years if you strictly followed all the stages of its assembly and observed all safety measures. With proper care, regular treatment of all wooden elements of the house with antiseptic agents, updating the varnish, as well as cleaning the grill and chimney, this design will last for decades and you will be able to gather with the whole family even on cold winter days around the fire and cook your favorite dishes , as well as treat them to your friends and acquaintances.

In this article we will tell you in detail how to quickly and beautifully build a hexagonal glass gazebo with a grill for your summer cottage. The area of this gazebo is about 10 square meters and it comfortably accommodates 10

people, and if you squeeze in, then 15.

We start with the basis of all basics - the foundation.

The most optimal foundation for a gazebo where there is a fire is a concrete slab. Of course, you can make a wooden floor, but in this case no one will insure you against fire. Don’t be afraid of a slab foundation; a gazebo with a grill is a fairly light structure and does not require fundamental structures; a slab 12-15 centimeters thick is enough. You will need only 5-6 bags of cement, gravel sand, and reinforcement to taste.

The side of our gazebo is two meters. We mark with pegs an even hexagon with sides of 2.1 meters (the foundation should be a little larger), and measure the “diagonals”.

When all three diagonals are equal, start working.

For ordinary soil, it is enough to dig a hole 25-30 cm deep and fill it with sand. There is no need to read gloomy “snips”, your gazebo, not a multi-story building, of course, if there is peat on the site, then you will have to remove all of it, down to the denser soil.

You will need 1.2-1.5 cubic meters of concrete - this is only 5-6 bags of cement, sand at the rate of one bucket of cement, three buckets of sand, crushed stone, the more the better, and reinforcement to taste.

When you fill the hole with sand, put waterproofing on top; cheap roofing felt or polyethylene left over from last year’s greenhouse will do.

When you have finished with the foundation for your gazebo with grill, let's start making it.

Naturally, we start with the purchase of material; the data given here is approximate and depends on your skills in using wood rationally.

Board for the bottom trim 50x150, 6 meters long, 3 pieces.

Board for frame 50x100 (or 40x100) 6 meters long, 47 pieces.

Planed board or timber simulator for a roof 25x150 (or 40x100) 6 meters long 47 pieces.

A timber simulator is 16 square meters; if you buy a length that is not a multiple of two meters, you will need much more material.

If your gazebo is glazed, then frames for windows and doors, it is optimal to buy them in advance at a hardware store; if you are in St. Petersburg, then they are always available in Vimos or Petrovich. Choose the frame size according to your taste.

Roofing material 20 square meters, due to the geometric complexity of the gazebo roof, it is optimal to use a soft roof such as flexible tiles

To make a grill house, you will need a special tool - a miter saw that can cut a 150x50 board at different angles (you can do this manually, but...), a circular saw that allows you to cut at a given angle, or an electric plane.

Let's start making the wall frame.

Cut 6 boards “1”.

Cut 12 boards “2-3”, don’t be afraid of the angle of 22.5 degrees, it is fixed on the vast majority of miter saws, when you cut the boards to size, make an angle of 60 degrees on the long side, and on six boards in one direction, on six to another.

Make part “5” and connection dimensions 5 and 4 according to the size of the frame you purchased.

You need to assemble 5 such structures and a similar structure for the entrance, only part 4 will be alone at the top, and parts 5 will be joined to part 1.

You only need to securely fasten part 1, everything else will be tied together with sheathing and your grill house will not go anywhere, due to the hexagonal design and shape of the gazebo roof.

Stage two, we sheathe the walls with a timber simulator as shown in the figure. When cutting the material, you will understand why we chose the internal size of 1950 mm, this allows you to use standard lumber without getting a lot of unnecessary scraps.

You will have to saw the edges of the timber simulator at 60 degrees, this will seem difficult, but in the future you will understand how much easier it will be in the future when assembling the gazebo.

When you have completed all the walls, you can start assembling, this operation takes 30 minutes, install the walls and tighten them with cuts.

Align the diagonals and secure the bottom trim with dowel nails to the slab, level the top by temporarily securing the opposite corners with boards.

Now let's start making the roof. We make blanks for the rafters from a board 100X50 (or 40) mm long 2400 mm on one side, remove the angle of about 8 degrees, and put together triangles for the roof elements of the gazebo, as shown in the figure.

When the six triangles are ready, we mount them on the finished walls. For ease of installation, nail a temporary strip to the underside of the triangle, which will allow the roof element to rest against the wall.

For greater convenience, install a long board in the center of the gazebo and attach it with self-tapping screws to the first section of the roof; fasten the remaining sections together with self-tapping screws, like wall elements. In similar designs of gazebos with barbecues, the upper part - a hole for a pipe, is very difficult to manufacture, in our design there are no elements difficult to manufacture, in the end the roof structure is so firmly connected by the sheathing that it allows you to hold not only a large mass of snow, but also several people on the roof.

Before finishing the sheathing, finally secure the roof elements to the walls.

We suggest welding a special structure; if this is difficult for you, use standard corners, having first bent them according to the angle of the roof.

We think with sheathing and soft roofing you will not have any problems.

How to glaze a gazebo. I hope you have made the correct openings for the purchased windows, now all that remains is to cover them with platbands on the inside, as shown in the figure, insert the frame and secure it to the platbands with self-tapping screws.

By analogy, insert the doors, and your gazebo with barbecue is ready. In this article, we tried to describe in as much detail as possible the process of making a gazebo with a grill, in the hope that our grill tables, barbecues and barbecues will perfectly complement the gazebo you have built.

How to accommodate guests and family during the cold season with minimal risk of freezing? What kind of garden buildings can be created on the site so that the family traditions of cooking barbecue in the open air do not suffer or fall into oblivion? There are answers to these questions. And they are hidden in the original Finnish grill house Grillikota.

Peculiarities

The main difference between such a building and a classic insulated gazebo is that a barbecue grill, an open fireplace, in a word, a fireplace for cooking and heating the room are built inside it.

The idea of a grill house comes from Scandinavia. It is completely reminiscent of Lapland igloos in its shape and sometimes filling.

The main features of the so-called “Finnish gazebos” can be determined by the following points:

- versatility of construction for any time of year;

- possibility of cooking indoors;

- the magical shape of a regular hexagon;

- a small and cozy room with a door and a couple of windows (in rare cases, such a gazebo is equipped with large windows);

- base - a solid reinforced concrete foundation, strong piles, in a lightweight summer version - a wooden patio;

- oven-hearth for preparing various dishes: from traditional kebabs and grilled vegetables to smoking fish and meat at home.

Despite the fact that the main purpose of the Finnish gazebo is barbecuing and gatherings in a narrow family circle at any time of the year, this type of construction has several different types. How do they differ from each other and what do they serve? Read on.

Kinds

Varieties of grill houses differ from each other in size (6 m2, 9 m2, 11 m2, 16.5 m2) and the materials from which they are built.

Wooden

A classic version of the Finnish gazebo, which not only makes the complex environmentally friendly, but retains and releases heat well. When building a grill house made of wood, you must take into account the fact that a sudden change in temperature can damage it. Therefore, the outer skin, as a rule, is made of moisture-resistant materials (for example, OSB sheets), and the frame and base are treated with special solutions.

Metal

Such barbecue houses in garden plots look very sophisticated and elegant. A metal gazebo will look very good with large windows or polycarbonate walls. Also, do not forget about treating the metal with anti-corrosion agents so that the grill house lasts as long as possible.

Stone

An excellent material for creating fundamental buildings. Such a winter gazebo will always come in handy and can serve you not only as a place to relax with the possibility of instant cooking on the spot. It is also perfect for accommodating guests at any time of the year, for use as a home mini-office and even for a children's indoor playground.

Foam and aerated concrete

They are practically insensitive to changes in seasons and temperatures, moisture resistant, and fire safety is at the highest level. The cost of these building materials is very economical. Another advantage of using foam and aerated concrete to build a grill house is its lightness. It will allow you to do without a heavy reinforced concrete foundation.

A barbecue gazebo in Russia often has an open shape. But fundamental buildings with a summer kitchen are extremely popular. Such joint buildings are designed to reduce the air temperature in the main house in the summer heat. The Finnish grill house for a summer cottage has a large number of options: with a hearth, with a barbecue, with a barbecue or with an entire universal oven in the center of the building. If necessary, such a gazebo can easily be combined with a bathhouse or sauna in the same building. In this case, the gazebo serves as a kind of dressing room with additional functionality.

For a children's indoor playground or an additional recreation area, remote from the food preparation area, you can equip a Finnish house with an extension. In this case, it will, of course, lose its authenticity, but will be more practical and spacious.

It is noteworthy that such wonderful gazebos can be equally easily and comfortably built independently or purchased ready-made.

Purchasing ready-made options

The homeland of grill houses - Finland - has prepared a big surprise for everyone who wants to get their own covered patio with a stove inside.

When purchasing ready-made grill houses, you should pay attention to two main options: standard economy option and extended premium. Despite the fact that the first is the most economical and the cheapest (its price usually reaches a maximum of 200-300 thousand rubles), its quality leaves no questions. In this regard, Finns are a very responsible people.

Economy gazebos are usually small in area, designed for a small number of people (no more than 6). Usually these are classic wooden buildings with the simplest, uncomplicated hearth. The economical design range contains inexpensive but very beautiful finishing elements, but all models are similar to each other both externally and internally. You will have to assemble such a house yourself, but it is not at all difficult. Detailed assembly instructions in Russian will help you assemble the gazebo with fireplace as quickly and accurately as possible.

Reviews of Finnish grill houses of the extended premium level are very mixed. Some note the large area of the finished gazebo and non-standard shape (sometimes large buildings are made in the shape of an octagon). Others react negatively to the same standard techniques and designs for an unimaginable price (500-700 thousand rubles).

Therefore, a much more unique and original option would be a grill house of your own production. Let's look at how to make a universal gazebo with a fireplace below.

If you decide to purchase a ready-made barbecue house, we offer you to watch the following video, in which you can see how to assemble it correctly.

Self-production

Before you start making a Finnish grill house yourself, you need to study all the main components of this type of structure, as well as acquire all the necessary materials and tools. The choice of target destination will also be important. What will it be: an open summer gazebo/veranda for relaxation or, perhaps, a solid stone house for all-season gatherings? Having answered these questions, you can begin designing.

Calculations

Like any architectural project, a country grill-gazebo requires careful development of the concept. First of all, you need to decide on the location of the building and its area. So, to create a Finnish gazebo with your own hands, you need to make drawings based on preliminary calculations. Here is a rough sketch of the simplest building:

From this it can be seen that calculations should be made both on the flat surface of the area where the grill house will be located, and in three-dimensional space. A standard grill house has a height of three to three and a half meters (including the roof). One side of the base (hexagon) can be 3.5-4 meters.

When you have finished with the drawings and calculations, you can begin to select the material for building a miracle house.

And in the next video fragment you can take the drawings of an octagonal-shaped grill house.

Selection of materials

Modern Finnish gazebos are made from tongue-and-groove pine boards - mini-beams. Despite its air and wind permeability, such material will retain heat in a gazebo with a central grill-stove in any weather and at any air temperature.

Multilayer wall panels are used to build a grill house. The outside walls consist of glued or profiled timber; for interior decoration, lining or any other simple wood material is more suitable. A special non-combustible insulation is laid between these layers.

All wooden surfaces of the grill house must be treated with Pinotex, which has fire-fighting and moisture-resistant properties. This is necessary so that using the stove inside a wooden room does not result in disaster.

Where should the stove be located?

The classic look of a grill house involves placing the oven in the center of the room. Before installing it, it is necessary to thoroughly prepare the foundation and foundation for the stove.

Often the foundation is a concrete platform on top of which a plinth is installed. This is necessary to place a vent in the floor of the gazebo - a pipe that will take air from the outside and supply it inside the fireplace, creating draft and freeing the room from carbon monoxide.

If the grill house is planned to be built on reinforced concrete piles, there is no need for a blower pipe, since the room will be naturally ventilated through the floor.

Above the stove there must be a hood and a chimney, the pipe of which goes out through the roof. Of course, the ideal option for such a house is the so-called sandwich chimney. You can visually examine it by paying attention to the gaps in the roof dome of the grill-gazebo, through which heated air will escape from the room.

The basis for the stove, as a rule, is a round table, at which guests and owners of the house will willingly sit.

Main stages of construction

Let's look at several basic steps that will allow you to build the grill house of your dreams as accurately as possible.

- Marking allows you to choose a place for construction where the foundation will be laid. First, the top layer of soil with vegetation is removed. Then the site is filled with sand, crushed stone and gravel, which must be compacted. If necessary, a blower pipe is laid. The site is again filled with the previous ingredients. The screed is poured.

- Frame installation The grill house provides a solid foundation for the future structure. Since the gazebo has a hexagon shape, it is necessary to install six vertical bars in each corner of the geometric figure. These bars are connected in three places: at the base, in the middle and at the top. The frame is considered correctly installed when the angle between the fastened vertical beams is 60 degrees.

- Manufacturing and installation of the roof. It consists of two main parts: the frame and the rafters. The first has six beams, each of which has two rafters.

- Grill house trim the outside should be made of moisture-resistant OSB material. After installing the frame and trim, you can move on to the doors and windows.

- Installation of the hearth in the center of the room is the final stage of creating a grill house. Installation of the stove is simple, but strictly according to the instructions for it. Don't forget about installing the hood and chimney.

Holidays in the country are always associated with a pleasant pastime, a noisy company of friends and cooking in the fresh air. Food in nature seems to taste better, and its smell, mixed with smoke, causes a strong appetite. You can create this atmosphere by grilling meat and vegetables. A similar roaster can be purchased in a store, but this pleasure will require a significant investment. In order not to spend extra money, you can build a grill for your dacha with your own hands.

General design

A grill is a special portable or stationary installation for preparing various culinary dishes over an open fire. The classic form of this design is a deep metal container in which grates are installed at different levels: the bottom one is for placing coals, the second is for cooking.

The grill is equipped with a lid, but some models are made without it. The first option is more functional, as it allows you to cook in three ways:

- straight;

- indirect;

- combined.

There are three types of grill:

- Classical.

- Connected to the mains. Grills of this type are used as additional equipment for professional and home kitchens.

- Operating on gas.

Options running on gas and electricity are more functional, but for country holidays many people prefer a charcoal grill.

Photo: grills of different types

A classic grill uses charcoal  A small cylinder is enough for a gas grill.

A small cylinder is enough for a gas grill.  Electric grill is convenient to use at home

Electric grill is convenient to use at home

Table: advantages and disadvantages of a classic grill

Not only coal can be used as a fuel material. Currently, there is an alternative to it - special briquettes. The use of this solid fuel ensures quick ignition and maintains a constant temperature for a long time. Briquettes are compressed blocks of different types of wood.

What is the difference between a grill and a barbecue?

Quite often, people do not find the differences between a grill, barbecue and barbecue. Each of the braziers has individual characteristics, despite the fact that they are used for cooking food over coals.

The barbecue has the simplest design. This device is a metal box. Food is cooked on metal skewers. Hot coals are located at the bottom of the box.

To ensure even heat, several small holes are drilled in the sides of the grill.

The only difference between a grill and a barbecue is that the first does not have a lid, while the second is equipped with a spit and lockable hatches for air supply.

Preparation: drawing up drawings, choosing material

To make a country outdoor grill, improvised materials are suitable. You can use a metal barrel, an empty gas cylinder or bricks.

The creation of each design requires careful preparation, calculations, drawings and diagrams

Barrel

When choosing this material, you should make sure that the body is not covered with rust, has no dents or other deformations.

For grilling, it is best to use a 200 liter container. The thickness of the walls of such a barrel should be from 0.8–1.0 cm. This is enough to prevent the metal from burning through regular use. The height of the case is usually 85 cm, which makes the design convenient to use.

Barrels with a wall thickness of less than 0.5 cm are not recommended.

For this grill you will need the following materials:

- Barrel with a capacity from 50 to 200 liters.

- To make the legs - 4 steel tubes, 110 cm long, 3–4 cm in diameter.

- To strengthen the structure, two similar tubes of 60 cm and two of 40 cm.

- 2 metal door hinges.

- For handles on the body and lid - 3 “U”-shaped parts made of thick reinforcement.

Gas cylinder

When making a grill, old cylinders are often used. Propane containers are best suited. The wall thickness in them is 3 mm, and the diameter is 29 cm. Thus, the body will not burn out, and the roasting pan will be quite spacious.

To make a grill from a gas cylinder, you can use materials similar to the option from a barrel.

Brick

Not every type of brick is suitable for building a grill. For this purpose, cladding (for the body) and fireclay (for the combustion part) are used.

To build such a grill you will need:

- 150 red bricks;

- 35 fireclay bricks;

- ready-made lattice or 30 steel rods 5 mm thick;

- reinforcing bars for foundation reinforcement;

- concrete mix grade M 300;

- sand;

- gravel.

This design requires a solid foundation in the form of a slab foundation.

The finished slab should be at least 10 cm wider than the grill structure on each side. Its size will be 160x160x20 cm.

To find out the volume of the concrete mixture, you need to multiply the height, width and length of the future foundation. For convenience, it is recommended to use these parameters in meters: 1.6·1.6·0.2=0.512 m³.

In order for a concrete base to be strong, it must be reinforced. To do this, use a mesh of metal rods, which is made from reinforcement with a thickness of 0.5 to 0.8 mm. The size of the mesh cells is 10x10 cm.

It is more convenient to calculate reinforcement in linear meters. To find out how many rods are needed for the mesh, you need to divide the length and width of the base by the cell size: 160:10 = 16 pieces - this is the number of rods placed across the width of the slab. Since it is square in shape, the same number of rods will be needed along the length of the slab: 16+16=32 pieces.

To further strengthen the foundation, you will need two such grids: 32+32=54 rods. Now you need to find out how many linear meters you need to purchase: 54·1.6=86.4 m.

Lattice

You can buy a grill grate at any hardware or sporting goods store, but it’s cheaper to make one yourself. To do this you will need stainless steel wire 3–5 mm thick.

You can also use:

- steel corners with a side width of 2 to 5 cm (for effective heat they are installed at an angle downwards);

- Cut strips 3–5 mm wide from sheet steel.

The optimal lattice size is 40x60 cm.

The rods will be located perpendicular to the wide part of the lattice. To find out how many rods are needed, you need to divide the length of the lattice by the width of the rod and the cell (usually this parameter is 5 mm). Now you can make the calculation: 60:1=60 pieces. The width of the grid will be 40 cm, therefore: 60·40=2400 cm, or 24 linear meters.

Required Tools

To make a metal grill you will need the following tools:

- hand circular saw;

- file;

- hammer;

- welding machine;

- electrodes;

- yardstick.

If desired, a metal grill can be equipped with a motor, which will be responsible for maintaining the required traction.

If a brick structure is being made, you will need:

- shovel;

- concrete mixer or solution container;

- trowel;

- building level;

- brush;

- cord;

- pencil or marker;

- polyethylene.

Step-by-step guide to building a grill house with your own hands

The grill house is a small building resembling a gazebo. The classic version of the design has an octagonal shape with closed walls, equipped with windows and a door. Inside the grill house, usually in the center of the room, a roasting pan with a chimney is installed. Benches are installed around it, parallel to the walls. Thanks to this placement, everyone inside the room will be able to observe the cooking.

An octagonal or round table is often placed around the grill.

The area of the room is designed to accommodate up to 12–15 people. The roof of the structure is made in the form of an octagonal cone, at the top of which there is space for installing a chimney.

A grill house is most often built as a frame structure, followed by insulation. This allows you to save on building materials.

Choosing a foundation type

When building a grill house, a permanent foundation is required, which can be:

- columnar;

- on screw piles;

- tape;

- slab

Each of these types of foundation is used depending on the quality of the soil. The choice is an important preparatory stage in the construction of a grill house, since the integrity of the entire structure depends on it.

If there is a predominant amount of sand in the ground in the area, then when the snow melts or during the rainy season, it can move. In this case, it is recommended to build a slab, strip or pile foundation.

Soil with a high content of clay and sandy loam is subject to deep freezing, causing it to become unstable. For such soil it is better to use screw piles.

In swampy areas, only pile foundations are also used.

Soil with a high gravel content is not subject to deep freezing and deformation under the influence of moisture. This type of soil is perhaps most suitable for construction, including for a grill house.

If the site is located on rocky soil, then there is no need to install a deep foundation. In such terrain, all types of foundations can be used, except for screw piles.

Instructions for constructing a structure for recreation

To build a grill house, you will need to complete the following steps:

- Select a site. Free it from debris and foreign objects.

- Make markings for the pit. Since a slab foundation was chosen for the grill house, the hole must be made 40 cm deep. For marking, it is convenient to use a cord stretched over stakes, which forms a perfectly straight line.

- Having dug a pit, you need to level its bottom.

- Pour in sand to form a uniform layer 10 cm thick. It will compress better if it is wet.

- Place a layer of gravel of similar thickness on top.

- Now it is necessary to install the formwork so that the foundation does not spread during pouring. To do this, you can use thick plywood, boards or OSB boards. From these materials it is necessary to make strips equal to the length (400 cm) and height (25–30 cm) of the pit.

- Install these wooden panels inside the pit, pressing each of them against the walls.

- To strengthen a concrete slab, it must be reinforced. To do this, make two identical gratings from rods 0.8–1.0 cm thick. The cell size should be 15x15 cm. Strengthen the intersections of metal rods with wire or plastic clamps. The frames should be laid in such a way that they do not touch, and the first does not touch the gravel. To organize such a space between the gratings, you can use halves of bricks.

- To ensure that the fire does not go out in the finished grill house structure, air supply to the roasting pan is necessary. To do this, you need to install a “U”-shaped pipe with a diameter of 15 cm and a length of 155, according to the diagram. One end of the pipe protrudes from the middle of the foundation, the other extends beyond it.

- Lay both gratings, maintaining the spaces between them.

- Now you need to pour the mixture inside the formwork. To do this, use concrete grade M 250 or M 300. To ensure that the mixture is evenly distributed throughout the entire space of the pit, it is leveled with a shovel. The top grille should be completely hidden under the concrete layer.

- A liquid foundation needs time to harden. In the summer, 3 to 5 days are enough for this, and in the cold months this period can last up to two weeks. Please note that direct exposure to the sun will cause the mixture to dry unevenly. This risks causing the foundation to become covered with cracks. Therefore, in the first two days after pouring, every 10–12 hours, the base must be moistened with water. In addition, the foundation must be covered with thick polyethylene. This will help prevent rapid evaporation of moisture and protect the base from sunlight.

- When the concrete has hardened, proceed to installing the bottom frame of the wooden frame. First of all, it is necessary to cover the surface of the foundation with a waterproofing layer. To do this, you can use liquid bitumen or roofing felt.

- Before use, all wooden structural elements must be treated with antiseptic impregnations and antifungal agents. For the bottom trim, it is recommended to use beams with a section of 150x150 mm. It is necessary to make cuts at the ends of each of them to create a “half-tree” connection.

- Install the beams onto the foundation. To do this, use anchor bolts or metal corners.

- Install floor joists inside the octagonal frame. For this you can use beams with a cross section of 150x100 mm. It is recommended to place them parallel to each other or from the internal corners of the structure to the center, closing them around the pipe.

- Now you need to install 8 support posts. To do this, you need to use beams with a cross-section of 150x150 mm and a length of 250 cm. They must be installed vertically on the lower frame. To do this, it is necessary to drill a hole with a diameter of 20 mm in the upper part of the corners of the lower trim. For the frame of the grill house, dowels (cylindrical wooden pins) with a length of 8 to 10 cm and a diameter of 20 mm will be required. To keep the racks in an upright position, they are reinforced with bevels.

- Install window sill boards between the vertical supports. For this you will need bars with a cross section of 50x150 mm.

- Using similar parts, install vertical posts for the window frame.

- Now you need to make the frame of the upper trim. For this you will need bars with a cross section of 100x100 mm. The upper structure is made according to the principle of the lower trim.

- When the frame of the grill house is ready, you can proceed to making the roof. For this, it is recommended to use beams with a cross section of 100x50 mm. It is more convenient to make the roof frame on the ground, and then raise it and fix it. The octagonal hole at the top of the structure must correspond to the diameter of the chimney pipe. In order to reliably strengthen the frame elements in the upper part, it is necessary to make a metal part, the elements of which repeat the shape of the beams.

- Now you need to install the base for the roofing material. To do this, you need to cut eight triangular fragments from OSB boards, the size corresponding to the sides of the roof.

- Using self-tapping screws, attach these parts to the top surface of the roof frame. Treat the cracks in the joints with polyurethane foam. The base for bitumen shingles is ready.

- Secure the roofing material on top.

- Now you need to create the floors in the grill house. First you need to install a layer of insulation. For this purpose, granulated expanded clay is suitable, which is poured between the lags. The thickness of the insulation must be more than 10 cm, otherwise the thermal insulation properties may be lost.

- Level the expanded clay. Install tongue and groove boards on top of it. Like all wooden structural parts, this material must be pre-treated with antifungal impregnations and dried.

- Install window frames and door.

- Insulate the walls of the grill house. To do this, it is necessary to install foam plastic slabs in the frame openings.

- Make interior and exterior decoration. What can tongue and groove boards be used for?

- Set up the broiler. Connect its elements with a pipe directing air. Secure the hood to the chimney.

- Place benches or seats parallel to the internal walls of the grill house. For this you can use beams with a cross section of 100x50 mm.

DIY smoker grill from a gas cylinder

The smoker grill is a universal design of interconnected thermal chambers for cooking meat and fish dishes, as well as vegetables and fruits. This unit combines a barbecue, smokehouse and grill.

The smoker grill structure consists of:

- metal stand;

- combustion compartment;

- horizontal camera;

- smokehouses;

- chimney pipe.

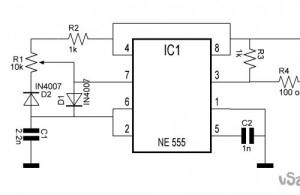

The operating principle of a smoker grill is that hot air passes through all chambers of the structure, exiting through the chimney. The hearth is located in the combustion chamber. This simple design requires careful preparation and drawing up drawings.

To make a smoker grill with your own hands, you need:

- Make thermal compartments. To do this, you can use old propane cylinders of different capacities. The thickness of the walls will withstand high temperatures.

- Make covers for each compartment. To do this, use a hand-held circular saw to cut rectangles from the body of the cylinders.

- Connect the bodies of the cylinders and cut out fragments with metal loops. For this you can use electric welding. The result will be functional lids to which handles need to be welded (they can be covered with wood).

- Having made cuts in the body of the cylinders, connect them by welding. The result should be a solid structure consisting of a firebox, barbecue and smokehouse. Weld a chimney pipe to the last chamber on top. The smoker grill can be equipped with thermal sensors.

- Make a stand. To do this, you can use metal corners, pipes or channels. For ease of moving the structure, its stand is equipped with wheels.

- It is necessary to make grates for the combustion chamber. To do this, you can use metal corners with a margin width of 10 mm or reinforcing bars with a diameter of 10–12 mm.

- For a barbecue you need a grate with cells no larger than 5 mm, which can be made from similar materials.

Video: smoker grill and barbecue from a gas cylinder

Despite modern technologies and well-equipped housing, every person lacks unity with nature, so most city residents try to spend their free time outside the metropolis, organizing summer gatherings. To do this, many people build a grill house on their plot of land, which is an ideal place for a comfortable family holiday and meeting friends. Thanks to the unique design, in such a building you can cook any food over an open fire, regardless of weather conditions, since the structure is built closed and reliably protects vacationers from wind, nasty rain and even snowstorms.

Description

A grill house is a gazebo that allows you to cook food directly inside the building. The main feature of this structure is that it can be used both in summer and winter. Typically, grill houses are built from solid wood in the form of a closed hexagonal structure with a door and windows. The foundation of a structure is usually installed from durable materials. The roof of the buildings is made of natural wood, giving it a triangular shape; a chimney is installed externally on the roof, which is connected to the fireplace.

The interior of the so-called Finnish houses is decorated in a standard way - in the center of the room there is a universal stove and additional accessories in the form of a smokehouse, spit and barbecue. In addition, for comfortable hanging out, the design is complemented by a tabletop and benches decorated with animal skins or pillows.

The construction of such structures is not particularly difficult. It’s quite possible to do it yourself, since all work is carried out in the same way as installing conventional gazebos. If the installation is carried out correctly, the grill house will not only serve as an excellent place for preparing dishes, but will also heat the room well in winter, creating all the necessary conditions for relaxation.

The main advantages of such buildings include:

- Possibility to cook grilled meat, fish, potatoes and hot drinks. The unique smell of smoke gives dishes an exquisite taste that cannot be compared with any restaurant menu.

- Convenient conditions for a good rest. To enjoy a live fire and please your loved ones with your grilled culinary masterpieces, you don’t need to leave the premises and build a fire. This is especially true when it is raining or snowing outside.

- Multifunctionality. Such structures are often combined with extensions for overnight stays and bathhouses. Thanks to this, the Finnish house turns into a full-fledged summer home outside the city.

- Comfortable layout. From the outside, a country house may seem small, but since it has a hex or octagonal shape, the rooms inside are spacious.

- Good air circulation. Despite the fact that the fireplace is located inside the buildings, modern ventilation systems provide fresh air.

As for the disadvantages, the only disadvantage of such houses is the high price. But there are many budget projects, thanks to which you can build an economical design option.

Projects

The birthplace of the grill house is Finland. Thanks to its convenient design and chic appearance, it has successfully proven itself all over the world, and most summer residents dream of such a building on their site. Before installing it, you need to carefully consider the layout and design of the structure. To do this, first a project is drawn up and the type of future gazebo is selected. The structure is most often made in the form of a hexagon, heptagon or octagon. The hexagonal shape is considered the most popular in projects., since its construction is carried out quickly and is inexpensive.

The heptagonal house is characterized by the presence of asymmetry; thanks to its interesting shape and additional edge, it can be originally decorated in any style. As for the octagon, it is chosen for large Finnish gazebos designed for a family of 6 people. Its installation is costly and labor-intensive, since construction requires a lot of materials. But it is worth noting that it is the octagonal gazebo that looks the most attractive and luxurious.

Such a house will be an excellent addition to the landscape design of a dacha located on a spacious plot of land.

In order to draw the drawings correctly, you also need to know the dimensions of the planned structure. A Finnish house is usually made with a diameter of 3 to 5 meters and a height of up to 2.5 meters. When choosing the dimensions of the structure, you should consider the following nuances:

- Number of persons, for which the building will be designed. For a family consisting of 4-5 members, it is enough to choose a project with a base diameter of 4 m. If guests often meet, it is advisable to install a gazebo of more than 5 m.

- Features of the arrangement. Depending on whether the room will be equipped with a grill, barbecue or fireplace, the area is calculated. In some cases, a stove is simply placed in the center of the building.

- Availability of additional rooms. Recently, projects with extensions have become popular. Houses with a bathhouse, sauna and kitchen are an ideal place to live outside the city, since one building has everything you need for this.

- Budget. Larger winter structures will require more expensive building materials, including thermal insulation. As for the summer gazebo, it will cost less.

An important indicator for the project is the material from which the house will be installed. Usually, it is built from mini-timber, but you can also use an edged board. The internal layout must be calculated so that the area of the room is divided into two parts: the larger one is intended for the table, and the smaller one is for the recreation area.

Installation

Installing a Finnish house, like any other building, requires a set of appropriate tools and building materials. Therefore, to build such a structure from timber with your own hands, you will need to prepare them in advance. As a rule, for this you will need a tape measure, an ax, a hammer, a tape measure, an electric drill and self-tapping screws. Installation work will not be particularly difficult if you have assembly instructions and special equipment for laying the foundation at hand.

As for the materials, great attention should be paid to their choice, otherwise the grill house will turn out to be fragile and will not last long. For construction you will need:

- chimney and smoke collector;

- lining;

- grill oven;

- thermal insulation;

- washers and nuts;

- Entrance door;

- medium-grained sand;

- crushed stone;

- polyurethane foam;

- double glazed windows;

- beam;

- edged board;

- soft tiles;

- paving slabs.

First of all, you need to decide on the location of the building. The structures are usually installed next to the main house between buildings. Before laying the foundation, the site is marked. To do this you need to do the following:

- remove the top layer of soil;

- fill the selected area with sand and crushed stone;

- carefully compact the layer of materials and prepare plastic pipes for installation;

- lay paving slabs and decorate its edges with curb stones.

Then you can proceed to the manufacture of the frame using support beams 2.5 m long and with a cross-section of 100 × 100 mm. Six beams are installed vertically and connected horizontally using beams 1.5 m long with a cross section of 80 × 80 mm. Fastening is done in three places: below, above and in the middle. In this case, it is important to check the angle between the fastened parts; it should be 60. In addition to the main beams, additional beams intended for doors and windows are also installed.

The next stage will be installation of the roof. To do this, first assemble its frame from boards with a cross section of 50 × 100 mm. It is best to choose a hexagonal design, thanks to which the internal diameter will create a hexagon proportional to the pipe for the hearth. The basis of the roof will be rafters prepared from edged boards. They need to be secured using metal corners and self-tapping screws.

The grill house is covered with OSB boards or other moisture-resistant material. It is recommended to line the inside walls with clapboard. When the walls are ready, it is necessary to install doors and windows, which are a mandatory component of Finnish structures. Upon completion of all construction work, a previously purchased fireplace is installed in the center of the room and the building is decorated to your taste.

Recently, many summer residents prefer to build grill houses in their garden plots. They fit beautifully into the landscape design of the site and serve as an excellent place to relax at any time of the year. To make such a design as convenient as possible for spending time, specialists It is recommended to equip it as follows:

- Supplement the construction with rooms for spa treatments. Using the warmth of the fireplace, you can create a good sauna. So, inside the gazebo there will be not only a place for a dining table, but also a steam room. In addition, it is best to purchase folding benches. If necessary, they will act as a sleeping place.

- Install ventilation. To do this, barbecues must be mounted together with an air exhaust pipe with a hole of at least 20 cm. Special patio decking is provided for grills; they provide excellent air exchange inside the room. The room should also be ventilated regularly.

- Think about the right layout. Typically, a grill with a chimney and a hood is placed in the center of the house, and benches are placed along the walls.

- Construction of Finnish structures can be performed using different types of foundation, the ideal choice is a columnar base, since a gap will form between the ground and the walls and there will be no need to install air vents. If the foundation is chosen in the form of a concrete slab, then pipes for ventilation must be laid in it.