Refrigeration equipment has become so firmly established in our lives that it is even difficult to imagine how we could manage without it. But classic refrigerant designs are not suitable for mobile use, for example, as a traveling cooler bag.

For this purpose, installations are used in which the operating principle is based on the Peltier effect. Let's briefly talk about this phenomenon.

What it is?

This term refers to a thermoelectric phenomenon discovered in 1834 by the French naturalist Jean-Charles Peltier. The essence of the effect is the release or absorption of heat in the area where dissimilar conductors through which electric current passes are in contact.

In accordance with the classical theory, there is the following explanation for the phenomenon: electric current transfers electrons between metals, which can accelerate or slow down their movement, depending on the contact potential difference in conductors made of different materials. Accordingly, with an increase in kinetic energy, it is converted into thermal energy.

On the second conductor, a reverse process is observed, requiring replenishment of energy, in accordance with the fundamental law of physics. This occurs due to thermal vibration, which causes cooling of the metal from which the second conductor is made.

Modern technologies make it possible to produce semiconductor elements-modules with maximum thermoelectric effect. It makes sense to briefly talk about their design.

Design and principle of operation

Modern modules are a structure consisting of two insulating plates (usually ceramic), with serially connected thermocouples located between them. A simplified diagram of such an element can be found in the figure below.

Designations:

- A – contacts for connecting to a power source;

- B – hot surface of the element;

- C – cold side;

- D – copper conductors;

- E – semiconductor based on p-junction;

- F – n-type semiconductor.

The design is made in such a way that each side of the module is in contact with either p-n or n-p junctions (depending on polarity). The p-n contacts are heated, the n-p contacts are cooled (see Fig. 3). Accordingly, a temperature difference (DT) occurs on the sides of the element. To an observer, this effect will look like a transfer of thermal energy between the sides of the module. It is noteworthy that changing the power polarity leads to a change in hot and cold surfaces.

Rice. 3. A – hot side of the thermoelement, B – cold side

Rice. 3. A – hot side of the thermoelement, B – cold side Specifications

The characteristics of thermoelectric modules are described by the following parameters:

- cooling capacity (Q max), this characteristic is determined based on the maximum permissible current and the temperature difference between the sides of the module, measured in Watts;

- maximum temperature difference between the sides of the element (DT max), the parameter is given for ideal conditions, the unit of measurement is degrees;

- permissible current required to ensure maximum temperature difference – I max;

- the maximum voltage U max required for the current I max to reach the peak difference DT max ;

- internal resistance of the module – Resistance, indicated in Ohms;

- efficiency coefficient - COP (abbreviation from English - coefficient of performance), essentially this is the efficiency of the device, showing the ratio of cooling to power consumption. For inexpensive elements this parameter is in the range of 0.3-0.35, for more expensive models it approaches 0.5.

Marking

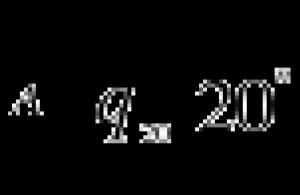

Let's look at how typical module markings are deciphered using the example of Figure 4.

Figure 4. Peltier module marked TEC1-12706

Figure 4. Peltier module marked TEC1-12706 The marking is divided into three meaningful groups:

- Element designation. The first two letters are always unchanged (TE), indicating that this is a thermoelement. The next one indicates the size, there may be the letters “C” (standard) and “S” (small). The last number indicates how many layers (cascades) there are in the element.

- The number of thermocouples in the module shown in the photo is 127.

- The rated current is in Amperes, for us it is 6 A.

The markings of other models of the TEC1 series are read in the same way, for example: 12703, 12705, 12710, etc.

Application

Despite the rather low efficiency, thermoelectric elements are widely used in measuring, computing, and household appliances. Modules are an important operating element of the following devices:

- mobile refrigeration units;

- small generators to generate electricity;

- cooling systems in personal computers;

- coolers for cooling and heating water;

- dehumidifiers, etc.

Let us give detailed examples of the use of thermoelectric modules.

Refrigerator using Peltier elements

Thermoelectric refrigeration units are significantly inferior in performance to compressor and absorption analogues. But they have significant advantages, which makes their use advisable under certain conditions. These advantages include:

- simplicity of design;

- vibration resistance;

- absence of moving elements (except for the fan blowing the radiator);

- low noise level;

- small dimensions;

- ability to work in any position;

- long service life;

- low energy consumption.

These characteristics are ideal for mobile installations.

Peltier element as an electricity generator

Thermoelectric modules can work as electricity generators if one of their sides is subjected to forced heating. The greater the temperature difference between the sides, the higher the current generated by the source. Unfortunately, the maximum temperature for the thermal generator is limited; it cannot be higher than the melting point of the solder used in the module. Violation of this condition will lead to failure of the element.

For mass production of thermal generators, special modules with refractory solder are used; they can be heated to a temperature of 300°C. In ordinary elements, for example, TEC1 12715, the limit is 150 degrees.

Since the efficiency of such devices is low, they are used only in cases where it is not possible to use a more efficient source of electrical energy. However, 5-10 W thermal generators are in demand among tourists, geologists and residents of remote areas. Large and powerful stationary installations powered by high-temperature fuel are used to power gas distribution units, meteorological station equipment, etc.

To cool the processor

Relatively recently, these modules began to be used in CPU cooling systems of personal computers. Considering the low efficiency of thermoelements, the benefits of such structures are rather doubtful. For example, to cool a heat source with a power of 100-170 W (corresponding to most modern CPU models), you will need to spend 400-680 W, which requires installing a powerful power supply.

The second pitfall is that an unloaded processor will release less thermal energy, and the module can cool it below the dew point. As a result, condensation will begin to form, which is guaranteed to damage the electronics.

Those who decide to create such a system on their own will need to carry out a series of calculations to select the power of the module for a specific processor model.

Based on the above, using these modules as a CPU cooling system is not cost-effective; in addition, they can cause computer equipment to fail.

The situation is completely different with hybrid devices, where thermal modules are used in conjunction with water or air cooling.

Hybrid cooling systems have proven their effectiveness, but the high cost limits the circle of their admirers.

Air conditioner based on Peltier elements

Theoretically, such a device will be structurally much simpler than classic climate control systems, but it all comes down to low performance. It’s one thing to cool a small volume of a refrigerator, another thing to cool a room or the interior of a car. Air conditioners using thermoelectric modules will consume more electricity (3-4 times) than equipment running on refrigerant.

As for using it as a car climate control system, the power of a standard generator will not be enough to operate such a device. Replacing it with more efficient equipment will lead to significant fuel consumption, which is not cost-effective.

In thematic forums, discussions on this topic periodically arise and various home-made designs are considered, but a full-fledged working prototype has not yet been created (not counting the air conditioner for a hamster). It is quite possible that the situation will change when modules with more acceptable efficiency become widely available.

For cooling water

The thermoelectric element is often used as a coolant for water coolers. The design includes: a cooling module, a thermostat-controlled controller and a heater. This implementation is much simpler and cheaper than a compressor circuit; in addition, it is more reliable and easier to operate. But there are also certain disadvantages:

- water does not cool below 10-12°C;

- cooling takes longer than its compressor counterpart, therefore, such a cooler is not suitable for an office with a large number of employees;

- the device is sensitive to external temperature, in a warm room the water will not cool to the minimum temperature;

- Installation in dusty rooms is not recommended, as the fan may become clogged and the cooling module may fail.

Tabletop water cooler using Peltier element

Tabletop water cooler using Peltier element Air dryer based on Peltier elements

Unlike an air conditioner, the implementation of a dehumidifier using thermoelectric elements is quite possible. The design is quite simple and inexpensive. The cooling module lowers the temperature of the radiator below the dew point, as a result, moisture contained in the air passing through the device settles on it. The settled water is discharged into a special storage tank.

Despite the low efficiency, in this case the efficiency of the device is quite satisfactory.

How to connect?

There will be no problems connecting the module; a constant voltage must be applied to the output wires; its value is indicated in the datasheet of the element. The red wire must be connected to the positive, the black wire to the negative. Attention! Reversing the polarity reverses the positions of the cooled and heated surfaces.

How to check the Peltier element for functionality?

The simplest and most reliable method is tactile. It is necessary to connect the module to the appropriate voltage source and touch its different sides. For a working element, one of them will be warmer, the other colder.

If you don’t have a suitable source at hand, you will need a multimeter and a lighter. The verification process is quite simple:

- connect the probes to the module terminals;

- bring the lit lighter to one of the sides;

- We observe the readings of the device.

In the working module, when one of the sides is heated, an electric current is generated, which will be displayed on the device display.

How to make a Peltier element with your own hands?

It is almost impossible to make a homemade module at home, especially since there is no point in doing so, given their relatively low cost (about $4-$10). But you can assemble a device that will be useful on a hike, for example, a thermoelectric generator.

To stabilize the voltage, it is necessary to assemble a simple converter on the L6920 IC chip.

A voltage in the range of 0.8-5.5 V is supplied to the input of such a converter; at the output it will produce a stable 5 V, which is quite enough to recharge most mobile devices. If a conventional Peltier element is used, it is necessary to limit the operating temperature range of the heated side to 150 °C. To avoid the hassle of tracking, it is better to use a pot of boiling water as a heat source. In this case, the element is guaranteed not to heat above 100 °C.

In this final article, I will tell you that these modules are not only capable of providing a temperature difference on their sides with a decent amount of electricity, but they are also capable of generating electricity if one side of the element is forcibly cooled and the other heated.

No load, temperature difference ~100°C

In these tests, a small module TB109-0.6-0.8 volunteered, with a surface area of only 3.12 sq. cm. Let me remind you of its role.., appearance and characteristics:

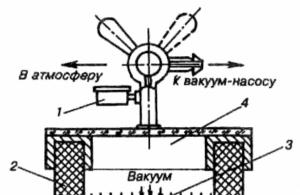

To test Peltier in electric generator mode, a small stand was assembled, which contains the following devices: a heater, a voltmeter, an ammeter and a load, a radiator and a piece of ice in a waterproof bag were also needed, and of course the experimental TB109-0.6-0.8 itself. The heater was a 20W 5.6 Ohm resistor, which was heated to about 80-90 degrees. To improve the thermal contact of the Peltier element with the heater, a Namaconda thermally conductive gasket was used, pulled out from some worn-out computer power supply.

Let's start testing.

The first test was carried out with a 1 Ohm load connected to the Peltier pins, and a room temperature radiator was used as a cooler.

We managed to get 0.117V from the module at a current of 119.5mA or 14mW, with a temperature difference of approximately 60 degrees.

Load 1 Ohm, temperature difference ~100°C

With a temperature difference of 100 degrees, the module produced better results, namely: 0.21V 0.22A or 46mW.

The following test was carried out with a load of 20 ohms.

Load 20 Ohm, temperature difference ~100°C

The module produced 1.31V at a current of 66mA or 86mW.

At idle, first photo, the module produced 2.19V.

Conclusion - Peltier modules can be successfully used to generate electricity. If the module contains 109 thermocouples, with an area of 3.12 sq. cm. with a temperature difference of 100 degrees, it was able to produce 86 mW at one and a half volts and more than 2 V at idle, then a module with a much larger area and temperature difference is enough to power a small LED illuminator or radio, or to charge batteries. But, unfortunately, their use is greatly limited by their price.

Examples of application: various TAGs, from portable tourist ones, which can be attached to a pot by the fire and listen to the radio, to RTGs, which are used to power remote, hard-to-reach autonomous objects (for example, lighthouses) or on space satellites.

Gratitude for the modules provided to the company – Radioelectronics.

Well, all the graphs are drawn, all the tables are filled out, now you can dream. In general, if you estimate the energy consumption on a hike to the maximum, you get the following:

GPS navigator - 0.3 W x 10 h = 3 W*h per day;

camera (Canon DSLR) - 8 Wh battery for 4 days = 2 Wh per day;

video camera (video recorder for capturing interesting moments of the trip, about 1 hour of video per day) - 1.6 Wh per day;

cell phone - about 0.2 Wh per day;

LED flashlight for illuminating the parking lot in the evening - 2 Wh per day.

Total we get: 3 + 2 + 1.6 + 0.2 + 2 = 8.8 Wh per day. Taking into account losses when charging the batteries of these devices and unexpected expenses, you can easily round this figure to 10 Wh per day, which is approximately equal to three AA NiMH batteries (3.2 Wh each). We will assume that this is the amount of electricity that allows you to comfortably travel along a previously planned route without limiting your creative urges. This calculation is more or less correct for a solo outing or a group of two people. If there are more people, then an additional consumer is added for each person, be it a cell phone or another camera. I think that for each “extra” participant you can safely add 1 Wh, that is, for a group of 6 people, a comfortable level of energy consumption will be 14 Wh or about 4.5 AA batteries. Let's assume that the hike lasts 10 days, then for a group of 2 people you will need 100 Wh of energy, this is 31 NiMH batteries with a total weight of 31 x 31.5 = 976.5 g. That is, almost 1 kg of batteries. If you take alkaline batteries, the best ones give out 2.2 Wh and you will need 45 of them. I don’t know their weight, but even if they are 25 g each, the total adds up to more than a kilogram. For a group of 6 people, the total amount of electricity is 140 Wh, which is almost 44 batteries weighing 1386 g or 64 batteries weighing even more. If you take with you LiPo batteries, such as modelers use, then for two people it will be a battery weighing 100 Wh ÷ 160 Wh/kg = 0.625 kg or 625 g. For a group of 6 people, the mass of the LiPo battery will be 875 g .

Now let's figure out how things are going with the thermogenerator. Let’s say we have a TEC1-12709 module (or modules), heat it no higher than 150 °C, cool it in a stream with a temperature of 15 °C, that is, on the cold side it will be 20 °C, the temperature difference is 150 - 20 = 130 °C. For such a value of temperature difference I do not have an efficiency indicator, I will have to count. We take two maximum values on the graph of efficiency versus current for TEC1-12709, for example 13.6 mW/°C for an average temperature difference of 71 °C and 15.7 mW/°C for 87 °C and calculate by what amount the efficiency has increased at increasing the temperature difference by 87 - 71 = 16 °C. It turns out to be 2.1 mW/°C. And then in proportion: if an increase in the difference of 16 °C led to an increase in efficiency by 2.1 mW/°C, then an increase in the difference by 130 - 87 = 43 °C will lead to an increase in efficiency by (43 x 2.1) ÷ 16 = 5.6 mW/°C. This means that the efficiency at a temperature difference of 130 °C will be equal to 15.7 + 5.6 = 21.3 mW/°C. As a result, we get 21.3 x 130 = 2769 mW or 2.8 W. This value is quite close to reality, judging by the fact that in some video experiments two modules produced 4...6 W. In order to obtain 10 Wh of energy using one module, the generator must operate for 10 ÷ 2.8 = 3.57 hours, and for 14 Wh - 5 hours. That is, if you use a thermogenerator consisting of 2 Peltier elements, then generating electricity even for a large group does not take very long.

The only major problem with generating electricity while camping using this method is heat dissipation on the cold side. The best and most optimal is water cooling, since water has a high heat capacity. In this regard, water tourists are luckier than cyclists: their method of transportation is connected specifically with water, and if you think through the design of the generator (it’s very strange why it has not yet been thought out and implemented on an industrial scale), then they can generate electricity while driving. The generator is partially submerged in water and partially floats on the surface. Fuel is loaded into the furnace as it is consumed, and everything is cooled with water from the outside. Fuel is collected and prepared at the rest stop.

If you don’t want to bother with collecting firewood and pine cones, then you can think about the design of a gas stove. It's worth doing a little math here. So we have:

liquefied gas cylinder for gas burners with fuel weighing 450 g;

composition: isobutane - 72%, propane - 22%, butane - 6%, in terms of weight this is 324 g, 99 g and 27 g, respectively;

the calorific values for these gases are 49.22 MJ/kg, 48.34 MJ/kg and 49.34 MJ/kg, respectively.

After multiplication and addition, we have 22.07 MJ in one liquefied gas cylinder. We take the efficiency of our generator to be 1%, therefore we get 220 kJ as electricity, which is 61.3 Wh. What can you compare it to? Well, for example, with 19 NiMH AA batteries. Not a lot and quite expensive, gas is not cheap.

Since using gas is expensive, you can come up with something using liquid fuel, such as gasoline. I scoured the Internet a little for a cheap catalyst for catalytic burners, but I couldn’t find anything other than chromium (VI) oxide obtained from ammonium dichromate. Yes, and not everything is so smooth with it, but if you wish, through a certain amount of experimentation you can achieve stable positive results here too. Catalytic heating pads made in China most likely use trace amounts of platinum group elements. If only there was a catalyst like in this heating pad, but larger for Peltier elements. The result would be a compact and lightweight generator. The calorific value of gasoline is 44.5 MJ/kg, density 0.74 kg/l, from one liter of gasoline we have 33 MJ of energy, at 1% efficiency this is 330 kJ or 91.6 Wh of electricity (28 AA batteries). A more budget option, but still collect and prepare what is available in nature free fuel is naturally more profitable, and it does not have one very unpleasant feature inherent in those supplies that are bought in the store - it does not run out at the most inopportune moment.

Continuing the topic of homemade devices.

This time we will talk about a temperature generator based on Peltier elements.

Peltier elements are such small (usually 4x4 cm) gizmos, consisting of ceramic plates and a bimetal between them, through which an electric current is generated when one side is heated and the other is cooled. Or vice versa, by applying current, we heat one side and cool the other. This property of Peltier elements is used in the manufacture of portable refrigerators, but I am primarily interested in the generating ability of these devices.

Indeed, very convenient. You heat one side of the element, cool the other - and you get enough current and voltage to charge, for example, a cell phone or other electronic devices. I generally have trouble with electricity, it doesn’t happen often, so I need such a thing vitally. No, of course, solar panels can partially solve the problem of lack of electricity. This, at this stage, I generally consider one of the best sources of alternative energy. Therefore, I also have a solar battery (which I’ll talk about later), small, but sufficiently powerful for me. It produces somewhere between 1 and 1.5 amperes at a voltage of 5 to 15 volts.

But the sun is not always there, so the thermogenerator turned out to be more necessary. Yes, even outside civilization it is necessary, and I think survivalists are also interested in such things.

To create a thermogenerator, not all Peltier elements are suitable, but only those that maintain a temperature of 300-400 degrees. Of course, it is possible to make a generator from ordinary elements, those used in refrigerators, but only as an experiment. Because as soon as you overheat, the element will fail. You can purchase high-temperature elements from the Americans or the Chinese. (A small digression about the Chinese: reading my blog, you may get the wrong idea that I have a bad attitude towards China or the Chinese. Quite the contrary, I admire China, which does not prevent me from believing that this is our most likely enemy. Again, the Germans too when -they were our enemy, and the French, and whoever was not. And so what? If there is a war, we will hate, but as long as there is peace, we are friends. Moreover, everything will end in the end, as was previously the case with other nations. And after all the wars, the Russians and the Chinese will become brothers forever. Amen.)

You can purchase elements from your compatriots, but at a fabulous price, and this is not our way.

So my thermogenerator is heated by an oil burner (using regular, cheapest sunflower oil).

Which is placed in such a collapsible housing, consisting of a tin can, a burner height regulator and the Peltier element itself.

The burner itself also consists of a can and a charcoal wick.

You can make such a wick using this video instruction.

Personally, I make such wicks from coals from a fire; advanced residents of large cities can simply buy charcoal in a store. Such a burner is good in itself; it can be used as a source of lighting, instead of candles. It doesn’t take much oil to work, it doesn’t smoke much, and it can burn for days.

This is a Peltier element; a radiator for cooling a computer processor, with a fan, is placed on top of it.

This is the burner fire level regulator. I made it from a dead CD-rom. It can be made from anything, as long as your imagination works.

I have a Peltier element (in this version, two or three elements, on top of each other, all lubricated with thermal paste) sandwiched between a cooling radiator and a heating radiator.

I filled the space around the element with rubber (from the heels of unnecessary shoes) and glued it all together with automotive heat sealant.

The cooling fan was made from a 3-volt motor from the same faulty CD-rom and the blades of a standard fan from a computer cooler. The engine and fan were connected using Chinese superglue and a disk holder from the same CD-rom. The result is a cooling fan that starts running at one and a half volts and consumes very little current.

For the heating radiator, I took a radiator from an old processor cooler.

The voltage, about 6-8 volts, goes to the converter, where it decreases to the five volts needed for the devices.

I have already written about this converter.

Here is the assembled generator itself. As soon as (within a minute or two) the generated voltage reaches one and a half volts, the cooling fan begins to spin, and the cold side of the element begins to cool. The thermogenerator enters operating mode within a few minutes. It can power LED garlands and charge electronic devices. My generator produces about 400 milliamps of current at 5 volts. The current strength depends on the element used. If possible, I will put better elements.

Also, this device, if you remove the generator part, can be used as a regular burner for boiling water. I usually fill the jar halfway and it boils within 10-15 minutes.

Hello, my name is Danil, and I'm paranoid. My paranoia lies in the fact that I am convinced of the imminent arrival of the Great Arctic Fox. It doesn’t matter in what guise this same arctic fox will come - if we remain alive, then, most likely, we will have to start living from scratch. And life is much more fun when you have something to charge the batteries in your flashlight and dosimeter. For those who think the same (as well as all those who are curious), I ask you to cut below (be careful, heavy photos).

Research part

Actually, why the Peltier element? It is much more logical to purchase a flashlight with a muscle drive (“ground beetle”), solar panels, or, at worst, build a windmill. Previously, I also thought that it was quite possible to get by with ground beetles. But it has a lot of moving parts, which are made by Uncle Liao from cheap plastic. The first breakdown in the conditions of the Great Arctic Fox - and you are left without electricity.Well, you ask, why not solar panels? There are no moving parts. I agree, I will answer, but in conditions of a nuclear or volcanic winter or under a two-meter concrete roof of a shelter, it is not so easy to catch the sun.

Windmill? What area should its blades be so that it can spin even in a weak wind? Moving parts, again. The windmill is suitable for permanent installation when equipping a long-term shelter.

Having considered these arguments, I became despondent. But soon I accidentally came across the website nepropadu.ru (no advertising, only a link to the source material). I sat on it continuously for two days, and in the process I came across a very interesting article about a wood chip stove made from a case from a computer power supply with a Peltier element on the side (link at the end of the post). There were a lot of skeptics in the comments, but the author wrote that he calmly charged the phone from a connected Chinese DC-DC converter... I was hooked.

Design part

To begin with, I ordered the same Peltier element from the Chinese on e-Bay (enough for experiments). It cost me 320 rubles. What pleased me was the expedited, tracking, but free delivery. Plus, the goods were sent literally an hour after payment (and it was on Sunday).While the Peltier element was traveling, I thought through the design of the future thermoelectric generator, found a suitable radiator with a fan (an ancient processor radiator worked perfectly), and also dug up on the Internet a circuit for a DC-DC converter with a maximum output current of 1 ampere at a voltage of 5 volts.

I did not consider it advisable to make a wood chip stove following the example from that article. The metal from which computer hardware is made is very soft; it will “sink” when exposed to high temperatures, and it will burn out quickly. Therefore, it was decided to make a “removable version” of the generator, which could be mounted on the side of a stationary stove or leaned against a pot standing on a fire. And in order to avoid frying the Peltier element over an open fire under such conditions, a heat-resistant but heat-conducting gasket was needed. To do this, I managed to get a piece of thick aluminum plate measuring 100x120x5 millimeters.

To press the Peltier element to the aluminum substrate, and, in turn, press the radiator to it, I decided to use a children's metal construction set that I once bought for robotics needs.

But the Peltier element arrived, and it was time for assembly.

Technological part

We had a radiator, an aluminum plate, a Peltier element, a handful of radio components, a piece of foil PCB and a variety of screws and nuts. I don’t remember further.So, all the components are assembled, you can start assembling.

I apologize for the plate that was marked and drilled in two places - it only occurred to me later that it would be nice to photograph the entire assembly process from the very beginning.

The first trouble that awaited me was the 12-volt standard fan on the radiator. Since I am going to produce only 5 volts, and even at a fairly small maximum current, this could create a problem.

First, I cast my bait in all the radio and computer stores in Perm, but nowhere was there a 5-volt 80x80 millimeter fan. And if there were, they were smaller in size and with a current of more than 200 mA, which was too much.

Then I did some digging on eBay and found that the fan I needed cost from 300 rubles. But it was pointless to hope for quick delivery, and so I left this option as a backup.

And only after all the searching I guessed to connect the standard 12-volt fan to a 5-volt voltage source. It turned out that it blows quite well, and at the same time does not consume very much current. Therefore, I decided to leave it for now, and after testing, if necessary, order a fan on eBay.

I marked an aluminum plate and drilled two holes in it for mounting the radiator and two for the voltage converter board. I made the holes with a diameter of 4 millimeters (for the screws from the designer), and on the outside I widened them to 7.5 millimeters to hide the screw heads. After that, I rounded the sharp corners with a file and walked with coarse sandpaper over all surfaces of the plate, and fine sandpaper where the Peltier element was pressed.

At this point, I considered the processing of the substrate complete and began manufacturing the voltage converter.

The pulse boost voltage converter is assembled on the L6920 IC, which starts operating at an input voltage of 0.8 volts and allows you to remove a fixed voltage of 3.3 or 5 volts, or variable from 1.8 to 5.5 volts, from its output.

The schematic diagram of the converter is typical and taken from the datasheet.

To obtain 5 volts at the output of the circuit, leg 1 is connected to the common wire. It is also configured to output a low level on pin 3 when the input voltage drops below 1.5 volts.

For the circuit, a printed circuit board was laid out, on which fastening to the base-substrate was provided using the same parts from the children's designer set. I am not worried about the board overheating, since it has forced cooling by an air flow blown from the radiator.

I had to tinker with the macro of the case that contained the microcircuit I bought. On the store's website it was stated that it was in the SSOP-8 case. As it turns out, there is no such case in the standard set of Sprint Layout macros. I found a drawing of the SSOP-8 case and made a macro, after which I routed the board. After a test print, it turned out that the microcircuit is somewhat wider and does not fit on its contact pads. Googling a specific chip model (L6920D) led me to the Chip-Dip website, where I learned that the IC with index D is manufactured in the TSSOP-8 package. Scratching my head, I found a drawing of this case, created a macro and re-routed the board. Now everything turned out to be correct.

The board was made using LUT and assembled. It turned out that soldering the TSSOP-8 case without a hair dryer is very inconvenient. But we are seasoned people, we soldered FTDI microcircuits with a pin pitch of 0.4 millimeters.

Now you can start installing the Peltier element and radiator. I coated the substrate and the radiator at the points of contact with the element with thermal paste. Then he tightened the resulting “sandwich” with nuts.

It turned out that the converter board does not fit, the input connector rests on the radiator, I miscalculated slightly. I turned the mounting brackets over, hung the board outside, and added two more brackets to protect the elements from mechanical damage. Here's what we ended up with:

Now you can check the functionality of the generator. I heated it on a gas burner. I decided not to install a fan for now.

To begin with, it turned out that I mixed up the polarity of connecting the element to the converter. Although everything seemed to be correct - the black wire is to minus, the red wire is to positive. However, the generator did not want to work. Then I changed the polarity of the element connection.

The generator started working - first both LEDs lit up, signaling the presence of 5 volts at the output and low voltage at the input, then the red LED went out - the voltage rose above one and a half volts.

To my displeasure, it turned out that without a fan, after a couple of minutes of operating the system, the radiator became noticeably hot. It won't work that way.

The next day, I walked around the metal market and several computer flea markets, but when I asked about 5-volt fans, they shrugged their shoulders everywhere and advised me to go “to that place over there” that I had already been to a couple of minutes ago. As a result, I went home empty-handed.

At home, I conducted an experiment on powering a standard 12-volt fan from the 5-volt output of the converter. The results did not please me - the converter, with obvious reluctance, turned off the red LED, and the fan twitched weakly for several seconds, trying to start. The air flow from the fan running at half power was not enough for normal cooling - the radiator heated up just as quickly, although it no longer burned my fingers. In the end, I decided to order the fan from Ebay.

Result

Despite the low efficiency of the Peltier element in the generation mode, I still got an intermediate result - when connecting a portable battery with a stated charge current of 1000 mA to the output of the converter, the generator was able to produce a current of about 600 mA. I think this current is quite enough to charge most gadgets in the conditions of the Great Arctic Fox.When the fan arrives (Ibay promises mid-March to early April), I’ll check the cooling. Plus, you will need to test the operation of the generator in “combat” conditions - at a fire.

I apologize for the quality of the photos - I'm not much of a photographer. Link to the article that inspired me: tyts.